Products & Services

- Siemens Tecnomatix Plant Simulation Software

- Siemens NX Tooling PLM Software

- Siemens Solid Edge Software

- Siemens Polarian Lifecycle Management PLM Software

- Siemens Teamcenter Solution

- Siemens NX CAM PLM Software

- Siemens Simatic IT Preactor PLM Software

- Solid Edge 2020 Buy 1 Get 1 Free Offer

- Siemens Teamcenter Software

- Siemens Academic Software Licenses

- Engineering Automation Rulestream Siemens PLM Software

- MES Siemens Manufacturing Execution System

- Siemens Mindsphere Open IOT Operating System

Siemens PLM Softwares

| Area of Usage | for Engineers & Architect |

| Suitable Platforms | 64-bit Microsoft Windows |

| Application | Product Design |

| Brand | Siemens |

| Service Type | Siemens Tecnomatix Plant Simulation |

| Service Mode | Online |

| Service Duration | 1-2 Day |

| Service Location | Pan India |

Smarter decisions maximizing overall production efficiency:

- Shifting business factors such as the demand for environmentally-friendly products, more sustainable production and increasingly competitive global markets require companies to constantly adapt and improve their business strate-gies. Launching faster, getting more from their capital investments and delivering quality products are always at the core of growth and prosperity even in demand-ing economic times.

- In the past, innovative products were enough to succeed, but in today’s world of unprecedented cost and regulatory pressures, successful manufacturers know they must leverage production capacity as a strategic advantage not simply as the cost of doing business.

- By innovating across their entire lifecycle, manufacturers realize a two-fold gain as they strive to build the right product and build the product right.

These manufacturers are increasing productiv-ity, optimizing more flexible capacity and more effectively leveraging capital investments by:

- Enhancing the visibility of process innovation across their enterprise

- Increasing speed to market by leveraging engineering assets in synchronization with manufacturing deliverables

- Capitalizing on emerging market opportunities with proven production flexibility

- Driving sustainable profitability through the continuous optimization of manufacturing resources and capi-tal investments

- Reducing cost by implementing more sustainable production strategies

- Leading companies leverage digital manufacturing in their product lifecycle because they know that the economic success of innovative products hinges on the performance of their manufacturing operations.

Tecnomatix bridges the gap between product design and product delivery:

- In today’s global marketplace, innovative products are the price of entry, but rapidly changing demographics and increasing competitive pressures demand process innovation as well. This is why leading manufacturers are increasingly turning to Tecnomatix® digital manufacturing solutions from Siemens PLM Software to make smarter decisions earlier for increasing productivity and agility while lowering costs and gaining a higher return on production investments

- Tecnomatix delivers process innovation by linking all manufacturing disciplines with product engineering, including pro-cess engineering and simulation, and production management. The Tecnomatix comprehensive portfolio of digital manufacturing solutions utilizes Teamcenter® software delivering an unmatched product and production inte-gration driving smarter decisions, better products, faster.

- Utilizing an open architecture, Siemens PLM Software delivers world-class solutions through open integrations that reduce deliverable timelines and increase the accuracy of your manufacturing planning efforts. By connecting product, process, resource and plant data, manufacturers are able to leverage a full arsenal of process-oriented capabilities recognized as the leading technology in the digital manufac-turing domain.

- A key component of a robust PLM strategy, Tecnomatix bridges the gap between product design and product delivery by managing both the design and execution of manufacturing processes in a fully associative data model. Tecnomatix maintains the crucial digital continuity of the product lifecycle, thereby helping manufacturers to bring more innovative products to market faster, as well as to leverage the power of global manufacturing operations, improve production efficiency, maintain quality and boost profitability.

View Complete Details

| Location/City | Pan India |

| Brand | Siemens |

| Country of Origin | Made in India |

| Service Type | Siemens NX Tooling PLM Software |

| Service Duration | 1-2 Day |

| Service Mode | Online |

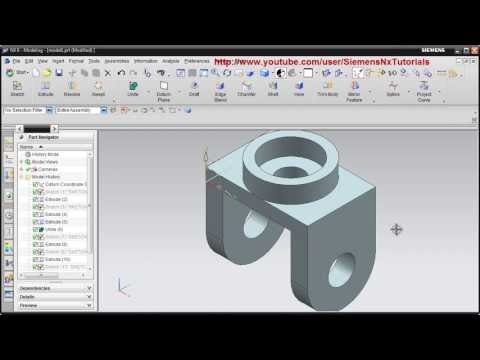

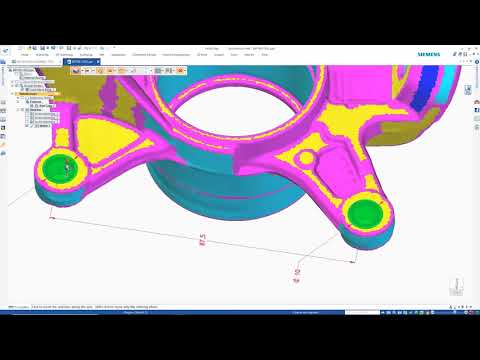

NX Tooling:

- NX delivers advanced automation, process simulation and integrated technology to improve productivity and ensure first-time quality intooling development.

The demand for speed:

- Tool design and manufacture is on the critical path for the development of many products.The demand for much shorter product delivery times, faster turnaround on design enhancements, lower supplier costs and increasing global competition have dramatic impacts on the toolmaking business.

The need for skills:

- The complexity of tool design and manufacture traditionally requires highly skilled people applying knowl-edge learned over years of practice. These resources are difficult to obtain or replace. Companies can gain com-petitive advantage by effectively leveraging specialized, best-practice knowledge in tooling development.

Improving quality:

- Quality of the end product depends directly on high-quality tooling. To achieve quality, tool designers and manufacturers must integrate their work with the product development effort. By dynamically linking tooling designs with product designs, compa-nies can automatically propagate design changes to production tooling, achieving first-time quality.

Reducing waste:

- To achieve speed and cost objectives, tool designers and manufacturers must eliminate wasted time, effort and resources – not only between product development and tooling development, but also throughout the tooling design, optimization and manufacturing process.

Transforming the process:

- NX™ software from Siemens PLM Software is a next-generation solution that transforms the tooling development process with advanced automation. Knowledge-driven applica-tions for tooling design and manu-facturing are fully integrated with the overall product development process in a managed environment that improves productivity, accelerates the process, reduces waste and cost and improves quality.

The NX Tooling advantage A complete solution:

- With NX, tool designers can share the same software environment as product and part designers and NC programmers. This enables the overall process to be faster and more efficient. Changes can be implemented more easily and with fewer errors. Wasteful re-entry of data is eliminated and multiple users can share the same 3D data. The tool designer, NC pro-grammer and manufacturing engineer can begin work even before the prod-uct design is complete.

Highly automated tool design:

- NX offers a powerful set of automated applications for mold and die design.These applications enable the user to complete the task of moving from part design to finished tool design in far less time than with the use of traditional CAD applications.

Maximizing productivity:

- Mold and die tool design in NX is driven by the knowledge of experienced designers built into the functions. The applications guide the user through each step of the process, multiplying the capability and maximizing the productivity of every tool designer.

View Complete Details

| Area of Usage | for Engineers & Architect |

| License Duration | 1 Year |

| Suitable Platforms | 64-bit Microsoft Windows |

| Brand | Siemens |

| Location | Pan India |

| Mode Of Service | Siemens Solid Edge Software |

| Service Duration | 1 Day |

Solid Edge

A portfolio of affordable, easy-to-use software solutions for product development.

Disruption in product design and manufacturing

Digitalization technologies are changing how products are designed and manufactured. Product design is becoming a cross-discipline collaboration, because product complexity is increasing exponentially and the complete design-to-manufacture process can now be fully digitalized. Such advances are improv-ing efficiency and effectiveness for all companies, enabling their success and growth. But for small and medium-sized businesses (SMBs) especially, digitalization can be a tremendous source of competitive advantage.

SMBs have become synonymous with innova-tion and disruption, but often lack the infrastructure to bring products to market quickly. Digitalization provides the ability to connect people, devices and businesses to lower or remove that barrier. Since SMBs are more agile, they can more easily leverage digital transformation to leapfrog the big incumbents. Today’s startups and SMBs can be tomorrow’s large enterprises.

Siemens Digital Industries Software empow-ers SMBs with solutions that address their unique needs. The Solid Edge® software portfolio delivers value, flexibility and choice: a modular, end-to-end solution that begins with an exceptional electromechanical design experience that is seamlessly inte-grated with market-leading applications for product optimization, data management, documentation, and manufacturing.

Digital transformation technology

Selecting a technology platform is an important decision, one that a company can live or die by. As a leading provider of manufacturing and engineering solutions for more than 170 years, Siemens is well posi-tioned to deliver the next-generation technologies that you need today.

Developed on Siemens’ industry-leading technologies, Solid Edge provides small and medium-sized manufacturers with the most innovative and comprehensive approach to product development on the market, and a tried and tested path for growth if and when you are ready.

Next-generation product development for today’s engineers

Synchronous Technology

The cornerstone of the Solid Edge portfolio is its market-leading computer-aided design (CAD) application. Developed from the ground up to be an open and extensible tool, Solid Edge with synchronous technology is the only CAD tool that provides you with the freedom to design naturally and iteratively with ease, whether you are working on a brand new design or editing existing parts, assemblies or products. That’s because synchronous technology contains built-in intelligence that interprets design intent regardless of where the design originated

Developed with foresight, Solid Edge with synchronous technology also enables col-laboration like no other professional CAD solution. In today’s open, highly connected digital design environment, interoperability is no longer just a nice feature to have − it is essential. Siemens synchronous technology provides the common language for the next generation of product design.

Additional components at the core of Solid Edge include game-changing technolo-gies such as generative design, convergent modeling and reverse engineering. Deeply embedded in Solid Edge, these robust features are reshaping the way products are developed

View Complete Details

| Brand | Siemens |

| Country of Origin | Made in India |

| Type Of Services | Siemens Polarian- Application Lifecycle Management PLM Software |

| Service Location | Pan India |

| Mode Of Service | Online |

| Service Duration | 2 Days |

Why you should consider Polarion ALM:

- Leading independent experts recommend that you consider Siemens PLM Software’s Polarion

- Ovum is a leading global technology research and advisory firm. Through its 180 analysts worldwide it offers expert analysis and strategic insight across the IT, telecoms and media industries. Ovum has one of the most experienced analyst teams in the industry and is a respected source of guidance for tech-nology business leaders, CIOs, vendors, service providers and regulators looking for comprehensive, accurate and insightful market data, research and consulting.

Ovum’s application lifecycle manage-ment (ALM) experts recommend that buyers consider Polarion ALM, for the following reasons:

- Polarion ALM provides a well-rounded ALM solution

- Only emerging ALM vendor with impressive Technology Score

- Polarion scored highly on the Customer Sentiment scale

- Impressive market traction...the solution is exactly what the market demands

- License costs are highly competitive

OVUM view:

- Initially released in 2005, Polarion ALM, Siemen PLM Software’s solution for application lifecycle management, was a relatively new entrant in the market. However, in this short timeframe, the company has been able to gauge indus-try sentiment well, and as a result was able to design its core offering – Polarion ALM – in line with market demand. Web-based access, collabora-tion, and low-cost application lifecycle management are the key focus areas of Polarion ALM.

Catalyst:

- Polarion offers a complete application lifecycle management (ALM) suite to provide greater visibility into the software development process. The portfolio has grown organically, lever-aging proven and reliable open source frameworks like Subversion, providing unified solutions that integrate the various disjointed process segments, each of which is typically addressed by a point solution. Therefore, today, the Polarion product provides an ALM suite that:

- Closely integrates ALM modules, facilitated by a solution-wide shared repository.

- Drives ALM with a workflow engine that underpins the whole lifecycle on one platform.

- Polarion is the category leader in. client engagement, service capabilities, product quality and customer support.

Market opportunity:

- The Polarion solution is a single mono-lithic application with closely integrated functionality and workflow, which Ovum believes is an advantage over ALM vendors whose solutions have grown inorganically and therefore depend on multiple repositories. Built around Web 2.0, Polarion’s solution has a strong focus on collaboration among distributed development teams, which is exactly what the market demands. Polarion ALM is targeted at application development teams (IT departments) within large enterprises and software development companies, and also product development projects supporting significant embedded software components. A lower-cost solution – Polarion Pro – is available, which may better suit small to medium-sized enterprises (SMEs).

View Complete Details

| Download Option | Free Download & Demo/Trial Available |

| Operating System | For Windows |

| Brand | Siemens |

| Type Of Services | Siemens Teamcenter Solution |

| Service Location | Pan India |

| Mode Of Service | Online |

| Service Duration | 1 Days |

Teamcenter Manufacturing Value proposition:

- The disclosure of information, technical data, specifications and other contained herein is deemed to be the proprietary intellectual property of Siemens PLM. No reproduction, copy or use thereof may be made without the express written consent of Siemens PLM. It is also understood and agreed that the disclosure of information must be kept confidential. To ensure the protection of such information, it is agreed that attendees limit disclosure of this document within its own organization on a need to know basis and shall not be communicated or distributed. Lastly, the information disclosed is forward looking based on Siemens PLM best estimates and may change based on technical, financial or external factors. No commitments of deliverables or timing can be asserted or assumed based on information disclosed.

Key Benefits of Manufacturing PLM Reducing the time to market:

- Enhanced collaboration Product and Manufacturing Engineering

- Enhanced Traceability, Faster Change Management

Enhancing Flexibility:

- Manufacturing plans comprehend product variability/complexity

- “What if” scenarios for optimized decision making

Increasing Quality:

- Manufacturing Simulation and validation integrated in PLM

- Up-to-date 3D work instructions delivered to the shop floor.

Increasing Efficiency:

- Ongoing process optimization based on Closed loop feedback of utilization data

- Reuse of common methods/tooling

Multi-BOM Manager (MBM) Overview and Benefits:

- MBM is a subset of MPP designed to support MSM current use cases plus additional powerful capabilities, e.g.

- Full accountability check (result summary view, propagation, advanced accountability, etc)

- Recipe based M-BOM creation

- Support Reusable Assembly use case

- Product Configurator

- DesignEBOM* (aka Part-CAD alignment for manufacturing)

- New future MPP developments will be reflected in MBM for the supported business use cases

- Training for MBM will be a subset of MPP training. No more different trainings for the same capabilities.

- Upgrading from MBM to MPP will be very easy as MBM is a subset of MPP, with same user experience and same system behavior, allowing customers to gradually expand their implementations smoothly

View Complete Details

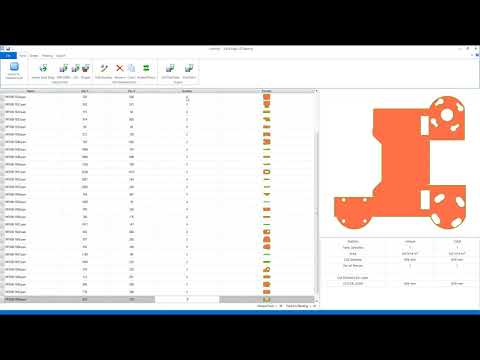

| Type Of Technology | CAM |

| Suitable For | Complex Parts Machining, Post processing & Machining Simulation,Mold,Die & Electrode Machining |

| Service Location | Pan India |

| Brand | Siemens |

| Service Type | NX CAM PLM Software |

| Service Duration | 2 Days |

| Service Mode | Online |

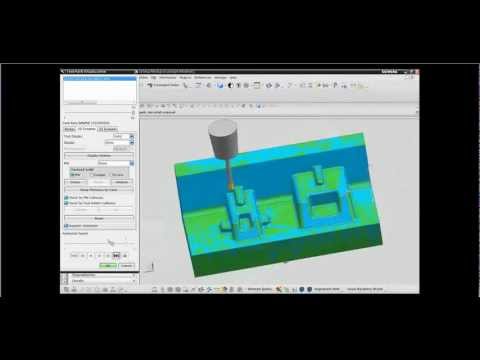

NX™ CAM software has helped many of the world’s leading manufacturers and job shops produce better parts faster. You can also achieve similar benefits by making use of the unique advantages that NX CAM offers

This short book is designed to introduce you to a few of the many powerful capabilities available inside NX CAM. With three simple hands-on exercises and instructions for accessing additional in-software learning resources, you can use this book to get started with NX CAM today!

Understanding NX CAM What is NX CAM:

- NX CAM is a complete set of NC programming software applications developed by Siemens PLM Software. Originally introduced as Unigraphics in 1973 for aerospace component machining, NX CAM’s rich history of technology development has advanced it into a market-leading NC programming application for many industries. NX CAM is a key application in a broader set of software solutions for design (CAD), simulation (CAE) and manufacturing (CAM).

How does NX CAM help me make better parts faster:

- More value in each key capabilityNX CAM delivers real differences through key capabilities such as its advanced programming, postprocessing and simulation func tion ality. Each NX module provides more than the standard functions you expect from typical CAM packages. For example, the integrated machine tool simulation is driven by output from the NX postprocessor rather than just tool path data. As a result, NX facilitates a higher level of program validation right inside its CAM system

- NX for manufacturingNX provides a complete set of NC programming capabilities in a single CAM system as well as an integrated set of manufacturing software applications. These applications facilitate part modeling, tool deign and inspection programming – all based on proven NX technology.

Right for your industry:

- NX has been adopted across many industries, delivering proven capability for manufacturing in the aerospace, automotive, medical device, mold and die, and machinery industries. Whether you have a small machine shop with a few machine tools or a large team of manufacturing engineers who utilize numerous machine tools, NX provides a solution to match your business needs.

- A leader in manufacturingWhen the right design and manufacturing software is matched with the latest controllers, machine tools and other shop floor equipment, you can implement a process chain that delivers maximum performance for your business. Siemens is an established leader in advanced machine tool controller technology and drive equipment. This combination of software and manufacturing equipment expertise enables us to develop part manufacturing solutions that provide you with unique and powerful advantages.

Key capabilities in NX CAM Advanced programming capabilities:

- NX CAM provides a wide range of functionality, from simple NC programming to multi-axis machining, enabling NC programmers to address many tasks using one system. The flexibility of NX CAM means that the most demanding jobs can be completed easily

Fixed-axis milling:

- NX CAM provides a wide range of 2-axis and 3-axis machining capabilities for prismatic and freeform parts – ranging from manual tool path creation and editing to advanced, automated cutting methods. Optimized roughing methods maximize the material removal rate without overloading the tool Fully automated rest milling removes uncut material from previous operations and eliminates air-cutting. A wide range of finishing techniques delivers superior surface finish quality. Automatic collision detection ensures safe machining of the most demanding geometry.

View Complete Details

| Brand | Siemens |

| Software Category | Manufacturing Advanced Planning, Advanced Scheduling |

| Operating Systems | Windows |

| Mode Of Service | Online |

| Service Type | Siemens SIMATIC IT Preactor PLM Software |

| Service Location | Pan India |

| Service Duration | 1-2 Days |

Enhancing the orchestration of your manufacturing process:

- Preactor APS Digitalization is changing everything, and manufacturers must react quickly and intelligently to unexpected changes, while being able to respond to shorter lead times and satisfy customer demands. These challenges are faced not only by large enterprises, but also small and medium businesses. Preactor APS products have been specifically developed to meet this need, using advanced algorithms that balance demand and capacity to generate achievable production schedules.

- Preactor APS products can be used for long-term strategic planning covering months and years, medium-term tactical planning with a few weeks planning horizon and for detailed sequencing and scheduling.

- Preactor APS can be installed out of the box, and can be customized and configured where necessary. It can be used standalone to manage planning and scheduling, and is also designed for integration with other software such as ERP, MES, Data collection, Forecasting, Demand Planning and OEE applications.

Advanced Planning:

- Advanced Planning software is a strategic decision tool designed to aid you in long and mid-term planning.

Advanced Scheduling:

- Advanced Scheduling software is an interactive, multi-constraint scheduling system that provides support for decision-making for overtime, order prioritization, production batches, due date negotiation and order processing.

View Complete Details

| License Duration | Perpetual |

| Service Location | Pan India Siemens GTAC |

| Operating System | For Windows |

| Download Option | Free Download & Demo/Trial Available |

| Course Name | Solid Edge Buy 1 Get 1 Free Offer |

| Course Type | Siemens Solid Edge Promo Offer |

| Product Type | Solid Edge CAD & CAM |

| Usage/Application | Design & Manufacturing |

| Type Of Technology | Solid Edge |

| Suitable For | Industrial Machinery & Heavy Equipment, Automotive & Auto Suppliers |

| Type | Offline |

| Type Of Service Provider | Certified Solid Edge Smart Expert Partner |

| Technology | CAD & CAM |

| Location | Pan India |

| Feature | Powerful 3D CAD CAE & Routing Software in One Product |

| Service Mode | Online Includes 1 Year Maintaineance Enhancement & Support |

| Required Processor | Minimum Core i5 and recommended Xeon Processor |

| Mobile App | For Android |

| Deployment | Server & Local |

| Database | SQL |

| Architecture | 64 Bit |

| Language Support | English |

| Others Modules/Features | Add on Module for CFD Simulation |

| Video Content | Yes |

| Search/Filter | Yes |

| Revision History | Yes |

| Publishing / Sharing | Yes |

| Offline Editing | Yes |

| Drag and Drop Interface | Yes |

| Data Visualization | Yes |

| Customizable Templates | Yes |

| Collaboration Tools | Yes |

| Animations and Transitions | Yes |

| Number of User | Single User |

| Available on Rent | Yes |

| Back Up | No |

| Support | Online, Business Hours, 24/7 (Live Rep) |

| Training | In Person, Live Online, Documentation |

| Provide Installation Service | Yes |

| Free Required RAM | 8 GB |

| Brand | Siemens Digital Industries Software |

Siemens is running a special year end promo offer for Solid Edge CAD & CAM PRO. We are certified Solid Edge Smart Expert Partner by Siemens Digital Industries & get expert support.

Solid Edge 2020 Offer Buy 1 Get 1 Free Offer:

- Buy SE Premium - Get SE Classic Free

- Buy SE Classic - Get SE Foundation Free

- Buy SE Premium - Get SE Foundation Free

Solid Edge CAM PRO Special Price Offer:

- CAM PRO 3 Axis Milling bundle ( No CAD)

- CAM PRO 2.5 Axis Milling with Se Foundation

- CAM PRO 3 Axis Milling with Se Foundation

- CAM PRO 5 Axis Milling with Se Foundation

Additional Information:

- Delivery Time: Anytime

- Packaging Details: E Download

View Complete Details

| Deployment | Online |

| Download Option | Free trial & download available |

| Service Duration | 1-2 Days |

| Device Compatibility | Desktop Only |

| Supported Platforms | Windows |

| License Duration | 1 Year |

| Languages Supported | English |

| Service Location | Pan India |

| Country of Origin | Made in India |

Teamcenter® software is a modern, adaptable product lifecycle management (PLM) system that connects people and processes, across functional silos, with a digital thread for innovation.

Key Features of Teamcenter PLM software

- Project Management

- Compliance Management

- Supplier Management

- Requirements Management

- Change Management

- Design Management

Why Teamcenter PLM software?

- Leverage the digital twin: Use digital twins to connect and optimize processes for designs, systems, software, simulation and visualization. Resolve problems before they become real.

- Collaborate and innovate: Connect people across your business. Automate and streamline product lifecycle processes. Provide visibility for everyone to make innovative product decisions.

- Rely on the leader: Start-ups to large enterprises - across industries - trust Teamcenter. Invest in the future with modern PLM of unmatched breadth, depth and usability

View Complete Details

Siemens Academic Software Licenses

Get Latest Price

| Course Mode | Online |

| Training Duration | 4 Days |

| Country of Origin | Made in India |

| Service Type | Academic Licenses |

| Brand | Siemens |

| Location | Pan India |

Siemens Digital Industries Software is committed to empowering the next generation of digital talent with the skills employers need. Today the academic partner ecosystem empowers more than one million future engineers and technologists at academic institutions worldwide to provide a strong pipeline of talent to enable a digital enterprise where engineering, manufacturing, and electronics design meet tomorrow.

- Partnering with Siemens Digital Industries Software helps academic institutions prepare the next generation of engineers for the digital mindset and experience.

- Contact us to know more about Siemens Centre of Excellence.

View Complete Details

| Also Provides | Professional Service Automation Software |

| Operating System | For Windows |

| Brand | Siemens |

| License Duration | 1 Year |

| Mobile App | For iOS, For Windows |

| Type Of Services | Engineering Automation Rulestream Siemens PLM Software |

| Service Location | Pan India |

| Mode Of Service | Online |

| Service Duration | 1 Day |

Rulestream for engineer-to-order process automation, Enabling manufacturers to rapidly engineer products to unique customer specifications.

Benefits:

- Deliver custom products at the cost, quality and speed of more standard-ized products

- Automate ETO product and processes in a fraction of the time required by traditional approaches

- Focus on knowledge capture, not software development

- Improve lead times, win rates and profitability

Comprehensive solutions for ETO process automation:

- You know the operational challenges that ETO brings to your organization. All too often the result is long bid and order engineering lead times,inaccurate cost and schedule estimates, margin-eroding errors and project schedule/budget overruns

- Rulestream is a powerful solution spe-cifically developed to help ETO companies like yours overcome those challenges. By using Rulestream to capture ETO process knowledge and rapidly engineer new products, even at the point of sale, companies have proven that they can increase sales win rates while shortening lead times and reducing overall costs. This ability to simultaneously grow revenue while lower operating expenses makes Rulestream a key asset for any company engaged in engineering products to order

Rulestream explained:

- Rulestream allows your product/process experts to capture the rules on how to engineer, design, manufacture and quote on jobs quickly and efficiently.

- Designed specifically to address the challenges facing an ETO manufacturer, Rulestream provides the tools and integrations needed to get you up and automating in the shortest time possible.

- Using rules your product experts cap-ture and maintain, Rulestream generates new product designs from the customer’s functional requirements. Through its easily configurable integra-tions with computer-aided design (CAD) and desktop systems, it can be used to accelerate bid-and-order engineering processes by automatically generating engineering outputs, including bills-of-material (BOMs), 3D models, drawings visualizations, work instructions and technical documentation. Rulestream has interfaces with other enterprise solutions, which means you can take full advantage of the information stored in these systems as well as transmit the configuration results and outputs to any downstream system, enabling enter-prise-wide process integration.

View Complete Details

| Location/City | Pan India |

| Type Of Service Provider | Individual Consultant |

| Mode Of Service | Online |

| Type Of Services | MES Siemens Manufacturing Execution |

| Brand | Siemens |

| Service Duration | 1-2 Days |

MES Siemens Manufacturing Execution System ensures that quality and efficiency are built into the manufacturing process and that they are proactively and systematically enforced. The Manufacturing Execution System connects multiple plants and sites, and integrates easily with equipment, controllers, product lifecycle and enterprise business applications, quality management and laboratory management systems, and many other applications. The result is complete visibility, control and optimization of production and processes across the enterprise.

Benefits of Siemens Manufacturing Execution System:

- Proactive Control & Quality

- Granular Enterprise Visibility

- True Continuous Improvement

- Brand Risk Reduction

- Improved Profit Margin

Data Collection & Acquisition:

- Siemens data collection and acquisition capabilities enable you to obtain operational production data that is associated with production equipment and processes.

Dispatching Production:

- Well executed production plans result in shorter cycle times, on-time deliveries and less demand on limited resources. Proper sequencing of manufacturing operations and work-in-progress (WIP) driven by intuitive task management makes it easy for operators to perform the right job at the right time.

Labor Management:

- Siemens PLM Software MES Labor Management provides the status of personnel and may include time and attendance reporting, certification tracking, as well as the ability to track production support functions performed by personnel. It automatically ensures that only qualified employees perform prescribed shop-floor and quality functions. Real-time verification fully supports regulatory and quality systems compliance. Operator Training and Certification enables you to establish manufacturing roles, define training requirements for various roles and process certification requirements, maintain training records and establish certification expirations.

Maintenance Operations Management:

- With Siemens PLM Software's Maintenance Management capabilities, you can track resource usage based on elapsed and usage time and production quantities; and, based on predefined limits, ensure that production does not outpace maintenance requirements. Maintenance Management provides visibility into resource issues and a detailed history of all activities. With this level of visibility, it is possible to determine true performance values for equipment.

Movement, Storage & Tracking of Materials:

- Siemens PLM Software MES Solutions provide the ability to manage and track the movement and storage of materials, in-process items and finished products, as well as the transfers between and within work centers.

Performance Analysis:

- Siemens PLM Software MES solutions provide up-to-the-minute reporting of actual manufacturing operations along with a comparison to historic and expected results. Performance results include measurements as resource utilization, resource availability, product unit cycle time, conformance to schedule, and performance to standards. Performance analysis may include SPC/SQC analysis and may draw from information gathered by different control functions that measure operating parameters.

Process Management:

- Siemens PLM Software MES solutions monitor production processes and provide decision support to operators for correcting and improving in-process functions. These functions may be intra-operational and focus specifically on machines or equipment being monitored and controlled within a single operation, as well as tracking a production process from one operation to the next.

View Complete Details

| Brand | Siemens |

| Type Of Services | Siemens Mindsphere Open IOT Operating System |

| Service Location | Pan India |

| Mode Of Service | Online |

| Service Duration | 1-2 Days |

| Working Temperature | 60 Degree C |

| Network Interface | WAN/LAN variable |

Mind Sphere The cloud-based, open IoT operating system:

- Every machine and system in your business provides a wealth of data with insights and benefits yet to be fully realized. Using MindSphere enables you to transform this data into productive business results. By connecting your machines and physical infrastructure to the digital world, MindSphere provides powerful industrial applications with advanced analytics and digital services to unleash increased productivity and efficiency across your entire business. MindSphere is the Internet of Things (IoT) operating system built as a secure and scalable industrial end-to-end solution for everything from connecting products, plants, systems and machines to unlocking your IoT data potential.

MindSphere offers you:

- Secure end-to-end solutions for connecting devices, storing data and developing and running applications on a managed service platform

- Extensive device, enterprise and database connectivity options to support a variety of IoT-ready assets

- Open platform as a service (PaaS) with numerous options for data exchange using Siemens open application programming interfaces (APIs) and native cloud accessibility.

- Fast development of robust industry-driven IoT solutions with advanced analytics capabilities

- Combined global scalability of Siemens as the number one automation provider, and the world’s largest cloud providers.

- MindSphere enables you to transform data into productive business results.

Connecting real things to the digital world:

- Industries undertaking IoT initiatives face the challenge of connecting to a wide range of assets quickly, affordably and securely from disparate locations. With MindConnect as part of the MindAccess IoT Value Plan, Siemens offers flexible, open connectivity solutions, including software and hardware options for connecting both Siemens and non Siemens assets to MindSphere.

- With the MindConnect IoT Extension, a software connectivity integration option in the MindAccess IoT Value Plan, virtually any IoT-ready asset from any manufacturer can be connected to MindSphere. Numerous field protocols are supported out-of-the-box, along with a wide range of hardware connectivity agents to bridge the gap for other protocols.

- Additionally, the MindConnect API enables programming of customer- or use-case-specific connectivity agents by interacting with MindSphere standardized APIs. The API for connectivity facilitates data transmission from assets to MindSphere, securely and efficiently.

View Complete Details

- Developed and Managed by IndiaMART InterMESH Limited