What We Offer

- Lab Colloid Mill

- Lab Tablet Press

- Laboratory Scale Conventional Coating Machine

- Lab Scale Mini Tablet Press

- Top Spray Lab Fluid Bed Equipment

- Lab Double Cone Blender

- Lab Octagonal Blender

- Lab High Shear Mixer Granulator

- Laboratory Scale Double Cone Blender

- Lab Paddle Mixer

- Lab Auto Coater

- Laboratory Scale Fluid Bed Coater - Bottom Spray

- Lab Conventional Coating Machine

- Lab Roll Compactor

- Lab Scale Octagonal Blender

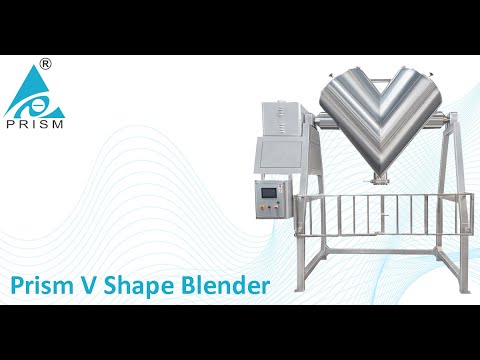

- Lab V Shape Blender

- Lab Tablet Coater

- Lab Ball Mill

- Lab Scale Triple Roller Mill

- Laboratory Scale Vibro Sifter

- Lab Multi Mill

- Laboratory Scale Oscillating Granulator

- Lab Scale Cone Mill

- Lab Fluid Bed Dryer

- Lab Coater

- Lab Planetary Mixer

- Lab Scale Planetary Mixer

- Laboratory Scale Pelletizer

Pilot and Laboratory Scale Machine

- Lab RMG

- Lab Fluid Bed Dryer

- Lab Fluid Bed Equipment

- Lab Multi Mill

- Lab Vibro Sifter

- Lab Oscillating Granulator

- Lab Communiting Mill

- Lab Blender

- Lab Roll Compactor

- Lab Tablet Press

- Lab Conventional Coating

- Lab Colloid Mill

- Lab Auto Coater

- Lab Extruder

- Lab Spheronizer

| Material | S.S |

| Automation Grade | Manual |

| Model | GMP |

| Condition | New |

| Model No. | PCDM-50 |

| Contact Parts | Stainless Steel |

| Customized | No |

| Power Rating (Horsepower) | 1 Hp |

| Verticle | Yes |

| Standard | cGMP |

| Finishing | Mirror |

| Color | Silver |

| Size | 50 Liter/Hour |

| Reverse Rotation | Yes |

| Brand | Prism |

The Laboratory scale colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size of a liquid suspended in another liquid. This is done by applying high levels of hydraulic shear to the process liquid. It is frequently used to increase the stability of suspensions and emulsions. The colloid mill is used for various applications such as Superfine grinding, homogenizing, emulsifying, dispersing, mixing and extracting of liquids, ointments and highly viscous products in pharmaceutical, cosmetics, suspensions & emulsion industry.

Additional Information:

- Item Code: PCDM

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Delivery Time: As desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Capacity | 200 Tablets per minute |

| Material | Stainless Steel |

| Driven source | Electric |

| Color | Silver |

Application

Lab Scale Single Sided Rotary Tablet Press is offered in three different Model viz. Tooling 8 Station with “D” Type, 10 Station with “B” Tooling and 12 Station with combined “D”, “B” and “BB” Type means 4 Nos. station of each type tooling. The Optional feature of New LABO Tab Xpress can provide with Force feeding system, Pre Pressing system and PLC Controls with MMI Touch Screen Operate Interface.

Additional Information:

- Item Code: PLTCMD

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Capacity | 1 to 27 Kg |

| Model | PCC |

| Material for Construction | Stainless steel |

| Power Source | Electric |

CONVENTIONAL COATING : Pan Size: 24”/30”/36”/42”/48”/60”

Application & Process:

Conventional coating machine are used to sugar coat tablets, pills, etc. for a variety of industries such as Pharmaceutical, Confectionery, Food and others. They are also used for rolling and heating beans and edible nuts or seeds.Salient Features:

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316/304 & non contact parts AISI 304.

- Conventional coating system for manual film coating and sugar coating. Machine is designed with fabricated structure fitted with SS enclosure which makes simple, cleanable outside covering and mounted on anti vibration pad.

Additional Information:

- Item Code: pcp

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

Lab Scale Mini Tablet Press

Get Latest Price

| Capacity | 14000 TABLETS/HOURS |

| Power Consumption | 1.5 HP, 3 |

| Material | Stainless Steel |

| Color | Silver |

| Grade | Automatic |

Lab Scale Mini Tablet Press :-Application

Lab Scale Single Sided Rotary Tablet Press is compact table top machine widely used for formulation development in R & D for small batch of tablet production. The New LABO Tab Xpress Lab Scale Single Sided Rotary Tablet Press is designed in an effort to exceed the highest cGMP requirement with use of advance technology and to ensure the most the modern ergonomic aspects and economical and efficient to tablet production. It is easy to operate, clean and maintain.

Salient Features:

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304. New LABO Tab Xpress Lab Scale Single Sided Rotary Tablet Press is offered in three different Model viz. Tooling 8 Station with “D” Type, 10 Station with “B” Tooling and 12 Station with combined “D”, “B” and “BB” Type - 4 Nos station of each type.

Additional Information:

- Item Code: PTCMD10

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Brand | Prism |

Fluid Bed Equipment – Dryer, Granulator & Coater : 30 Kg to 500 Kg. Capacity

High Precision Fluidize Drying, Granulating, Agglomerating & Coating Process Technology

Prism Fluid Bed Processing involves drying, cooling, agglomeration, granulation and coating of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Chemicals and Biochemical, Food and Dairy Industries.

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- High Mixing Precision, Short Batch Time, Problem free Cleaning and Residue Free Discharge.

- Only Top spray Granulator Model

- Only with Bottom Wurster coater

- Combo model with Granulator and Pallets Coater.

- Flame Proof Electrical.

Additional Information:

- Item Code: PPMFBE

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Usage/Application | Pharma |

| Color | Silver |

| Design Type | Standard |

| Automation Grade | Automatic |

| Voltage | 220 V |

| Loading Capacity(Litre) | 5 TO 2000 kg/batch |

| Frequency | 50 Hz |

| Body Material | Stainless steel |

| Safety Guard | Yes |

Application & Process:

The prism compact NewLABO BLEND- Octagonal/ “V’ Shape / Double Cone and Bin blender is a multi purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flow ability of the material for Tabletting and capsules.

The basic machine consists of product mixing drum and it’s available in different size and shape. A product drum mounted with single ends by hub shafts on directly and it’s rotate in shaft axis. The drive is completely closed with SS 304Q machine body. The drive unit consisting of motor, reduction gear box and control panel.

New Design Features:

- Designed strictly compliance with the stipulation of cGMP.

- Product contact parts AISI 316/ 316 L Quality & Food grade silicon

- A C Frequency drive for variable speed of product container.

- Product contact parts are mirror finished and non contact parts are matt finished.

- Safety reeling with limit switch.

- Electric Control panel with cycle timer and RPM indicator.

- Option for Interchangeable product bowl with different capacity 1 kg to 25 kg batch size.

- Option for different shape of product container like Octagonal, “V” shape, Double cone and Bin Type.

- Option for PLC Controls with MMI Touch screen interface.

Safety Features:

- Safety reeling with limit switch.

- Auto stop when process time completed.

- Overload relay controls.

Multi purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flow ability of the material for tabletting and capsules.

Additional Information:

- Item Code: PDB

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Delivery Time: As desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Automation Grade | Automatic |

| Condition | New |

| Contact Parts | SS 316 |

| Color | Silver |

| Brand | Prism |

| Model | cGMP |

Uniformed Dry Mixing & Blending Technik

Application & Process :

The prism compact NewLABO BLEND- Octagonal/ "V' Shape / Double Cone and Bin blender is a multi purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flow ability of the material for Tabletting and capsules.

The basic machine consists of product mixing drum and it's available in different size and shape. A product drum mounted with single ends by hub shafts on directly and it's rotate in shaft axis. The drive is completely closed with SS 304Q machine body. The drive unit consisting of motor, reduction gear box and control panel.

Additional Information:

- Item Code: PPMKOB

- Port of Dispatch: Mumbai

- Production Capacity: 1 Kg to 25 Kg

- Delivery Time: 4 to 6 weeks

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

| Model | PRMG |

| Automation Grade | Automatic |

| Power Source | 415 |

| Condition | New |

| Material Grade | S.S 304 |

| Contact Parts | SS 316 |

| Phase | 3 phase |

| Brand | Prism |

| Material | S.S 316 |

Application

The overall concepts of the New LABO mix steam from similar of process based on production model and common needs of consistent processing and ease for operation and cleaning. The mixing bowl designed with shallow and wide diameter for guarantee a consistent product vertex mixing by main impeller and granulated by chopper blade.

The Prism compact LABO mix High Shear Mixer Granulator is a multi purpose processor equally suitable for high speed dispersion of dry powder, aqueous or solvent granulations and effervescent products and melts pelletization.

Additional Information:

- Item Code: PRMG10

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Capacity | 50-600 kg |

| Power Source | Electric |

| Motor | 15 HP |

| Color | Silver |

| Material | Stainless Steel |

Lab High Shear Mixer Granulator

Application & Process:

The Prism compact LABOmix High Shear Mixer Granulator is a multi purpose processor equally suitable for high speed dispersion of dry powder, aqueous or solvent granulations and effervescent products and melts pelletization.

The overall concepts of the New LABO mix steam from similar of process based on production model and common needs of consistent processing and ease for operation and cleaning. The mixing bowl designed with shallow and wide diameter for guarantee a consistent product vertex mixing by main impeller and granulated by chopper blade. A typical 3 minute dry mix operation than granulation by adding binder manually or spraying unit with pressurized. A free flowing granulate is produced after 3-5 minute and the granules are than rapidly discharge

Additional Information:

- Item Code: LPRMG

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Automatic Grade | Automatic |

| Color | Silver |

| Loading Capacity(Litre) | 1 kg to 10 kg |

| Body Material | Stainless steel |

PRISM® NewLABO BLEND: Lab Blender/ Double Cone

Uniformed Dry Mixing & Blending Technik

Application & Process:

The prism compact NewLABO BLEND- Double Cone is a multi-purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flowability of the material for Tabletting and capsules.

Additional Information:

- Item Code: PPMDCB

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Automatic Grade | Automatic |

| Material | Stainless Steel |

| Capacity | 5 liter to 8000 liter |

| Model | GMP |

| Condition | New |

| Brand | Prism |

LAB Mass Mixer / Ribbon Mixer / Paddle Mixer

Application & Process:

The Laboratory Mixer is designed for uniformly mixing of dry and wet material and especially suitable for Pharmaceutical, Food and chemicals industries.

The mixer consists of a rigid fabricated structure motor, gear box, mixing drum, stirrer and tilting device. The mixing drum complete with stainless steel body, stirrer and tilting device. The mixing drum complete with stainless steel body, stirrer and sealing arrangement. The drive of mixing paddle is through suitable gear box and motor. The tilting device is provided to make easy the unloading of the material and easy cleaning of the mixing drum. The Mixing stirrer can be provided different shape Ribbon type / Paddle type according to machine.

Additional Information:

- Item Code: LPM

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden Packing

View Complete Details

| Material | SS 316 |

| Capacity | 1 Kg TO 17 Kg |

| Model | Labocoata |

| Brand | Prism |

| Automation Grade | Automatic |

| Condition | New |

| Design Type | Standard |

| Finishing Type | Mirror & Matt |

| Size | 12",14",16",18",20" |

Lab Tablet Coater

High Efficiency and Intelligent Film Coating Technique

Application & Process :

The prism compact NewLABOcoata- Lab Auto Coater is high efficiency and intelligent automated film & sugar coating advance technology is mainly used in pharmaceutical and food industries. Featuring mechatronis and confirming to the requirement of cGMP. It is a high efficiency, energy saving, safe and clean equipment for film & sugar coating of tablets, Pills and candies with film - organic solvent and aqueous coating.

The tablet to be coated make continuous complicated orbital motion the closed rotating Drum under the action of a streamline of Baffles. During the motion coating medium automatically sprays according to the technological process and rational technological parameters, at the same time hot filtered air supplied under a negative pressure. The hot air penetrates through the tablets core layers and is discharged from the bottom of the layers, so that the coating medium sprayed on the surface of the tablet cores will dry rapidly and evenly, thus forming a solid and smooth surface film on tablet.

New Design Features :

- Designed strictly compliance with the stipulation of cGMP.

- Product contact parts AISI 316/ 316 L Quality.

- Complete automatic coating processes with advanced PLC Controls with HMI touch Screen.

- Perforated coating pan with mixing baffles, anti slide ribs and variable speed by VFD.

- Enclosed pan drive through reduction gear box and motor.

- All doors, safety guards and covers are provided with a suitable food grade seals.

- The perforated pan has a suitable mouth opening for tablet Charging and Discharging which provided with stainless steel cover and a glass window for process visualization.

- Front Entry stainless steel arm, with facility to adjust the angle of spray guns is provided.

- Atomized Spraying system with solution holding tank, peristaltic pump, atomized spray gun and auto electro-pneumatic spraying controls system through PLC

- Inbuilt Inlet Air handler with blower, electric heater, 20 & 5 micron filter & 0.3 micron HEPA.

- Inbuilt Exhaust air blower with 20 micron filter.

- Inlet air flow and exhaust air flow can be adjusted through VFD of blower.

- Differential pressure indicator for pan and HEPA filter.

- WIP/CIP system for easy cleaning

- Option for Interchangeable pan.

Safety Features :

- Explosion proof electric motor.

- Auto shutoff system for over limit temperature/ heating & Auto stop when process is completed.

- Air pressure switch installed to ensure pressure is in limit.

- Differential pressure indicator for HEPA Filter.

- Overload relay controls.

Additional Information:

- Item Code: PPMACL

- Port of Dispatch: Mumbai

- Production Capacity: 1 Kg to 27 Kg

- Delivery Time: 4 to 6 weeks

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

The Laboratory Scale Fluid Bed Coater - Bottom Spray model Fluid bed technology is a offer an effective and efficient method for drying, granulating, agglomerating and granules/ pellet coating.

The Fluid Bed Equipment has universal application:

- Designed strictly compliance with the stipulation of CGMP.

- Product contact parts AISI 316 / 316 L Quality & Food grade silicon

Additional Information:

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Material | SS |

| Model | PCP |

| Size | 12",14",16",18",20" |

| Brand | Prism |

The Laboratory scale conventional costing machine is ideal for film and sugar coating. The machine is available with 12", 14",16", 18" and 20" size of stainless steel coating pan. The machine is designed with fabricated structure fitted with SS enclosure and drive unit of motor and reduction gear box. Machine has variable speed drive to achieve 5 to 15 RPM by variable speed pulley. The machine is mounted on anti vibration pads which avoids foundation and vibration.

A hot air blower system is provided separately on trolley for easy cleaning and setting. The system has thermostat controller to selected temperatures between 40º C to 100º C by electric Heater. The complete systems fitted suitable motor, blower, piping and nozzle for hot air flow.

Additional Information:

- Item Code: Labcoac

- Port of Dispatch: Mumbai

- Production Capacity: 1 Kg to 27 Kg

- Delivery Time: 4 to 6 weeks

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

| Model | cGMP |

| Material | SS |

| Brand | Prism |

Application

The material in form of powder passes through the two counter rotating rolls of roller compactor under very high pressure. As the volume decreases through the region of maximum pressure, the material is formed into a solid compact sheet or flakes of ingredients. These flakes or compact sheet of ingredients are reduced in size to obtain the desired grain size. The machine takes extra care to prevent the generation of fine during this process.

Additional Information:

- Item Code: PRC10025

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Brand | Prism |

| Material for Construction | Stainless steel |

| Power Source | Electric |

| Automatic Grade | Automatic |

Application & Process:

The prism compact New LABO BLEND - Octagonal is a multi purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flow ability of the material for Tabletting and capsules

New Design Features:

- Designed strictly compliance with the stipulation of cGMP.

- Product contact parts AISI 316/ 316 L Quality & Food grade silicon.

- Easy to interchangeable Product container any shape with capacity of 1 kg to 10 kg.

- Rigid drive through gearbox and motor.

Additional Information:

- Item Code: POB

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: AnySeaport

- Delivery Time: AsDesiredbyCustomer

- Packaging Details: Export Worthy Packing

View Complete Details

| Model | GMP |

| Material | SS |

The prism compact new labo blend- octagonal/ “v’ shape / double cone blender is a multi purpose mixer suitable for effective and uniformed mixing, lubricating and blending process of dry powder and granules homogeneously for facilitating better flow ability of the material for tabletting and capsules.

The basic machine consists of product mixing drum and it’s available in different size and shape. A product drum mounted with single ends by hub shafts on directly and it’s rotate in shaft axis. The drive is completely closed with ss 304q machine body. The drive unit consisting of motor, reduction gear box and control panel.

Additional Information:

- Item Code: PPVB

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Delivery Time: As desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

Lab Tablet Coater

Get Latest Price

| Model | PAC |

| Brand | Prism |

| Automation Grade | Automatic |

| Material | SS |

| Condition | New |

| Material Grade | SS316 |

Application

The tablet to be coated make continuous complicated orbital motion the closed rotating Drum under the action of a streamline of Baffles. During the motion coating medium automatically sprays according to the technological process and rational technological parameters, at the same time hot filtered air supplied under a negative pressure.

Additional Information:

- Item Code: LABOcoata12

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

Lab Ball Mill

Get Latest Price

| Capacity | 1 Kg |

| Usage/Application | Pharmaceutical Industry |

| Material | Stainless Steel |

| Rotation Speed | 60 RPM |

| Motor Power | 0.5 HP |

| Phase | Single Phase |

| I Deal In | New Only |

| Power Source | Electric |

| Country of Origin | Made in India |

The Laboratory stirred Ball Mill is mainly used for various grind able materials dry or wet type in Chemical, Pharmaceuticals, Herbals and Catalyst Industries for super fine micron size grinding. A lab stirred ball mill is an crucial device in terms of the rapid, reproducible pulverizing, milling or grinding of a massive kind of materials. Depending at the configuration and preference of mill, samples may be soft, elastic or fibrous however additionally difficult or brittle.

Our lab stirred ball mill machines effortlessly meet laboratory and business grinding requirements. Loads with heavy obligation construction, excessive pleasant metallic grinding media balls, those ball generators effectively contend with any pulverizing, milling or grinding activity that you could deliver it.

- Design as per stringent GMP Model.

- Contact parts of SS 316 and non contact parts of SS 304.

- Variable speed for drum up to 60 RPM.

- Drive shaft with rubber coating.

Additional Information:

- Item Code: PPBM

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

Lab Scale Triple Roller Mill

Get Latest Price

| Automatic Grade | Automatic |

| Design | Standard |

| Power Source | Electric |

| Material | Stainless Steel |

| Model | PTRM -80 |

PRISM LABORATORY SCALE TRIPLE ROLLER MILL is designed for small batch size and flexibility to a bench top mill. In a Triple Roller mill, particle size are reduced and agglomerates are dispersed by the combined crushing force of the rollers and the extremely high shearing force resulting from different roller speeds. Since the entire product is fed into the gap between the rollers, the result is precise, controllable and narrow particle size distribution. By setting the gap width, particle size can be controlled easily and accurately, down to the micro level.

Three roll mills can be used to process a wide range of products with diverse rheology- from low viscosity materials of 200 cPoise to thick paste of more than 1,000,000 cPoise. Three roll mills enable a medium or high viscosity product to be dispersed with minimal liquid. Since liquid materials do not have to be dispersed, they can be added later. Three roll mills provide outstanding control of product temperature, since the product is processed as a thin film on the roller. As result, the product can be heated of cooled to the desired temperature.

Salient Features:

- Design as per stringent cGMP requirement.

- All contact parts are in S.S.316 non contact parts in S.S.304 Quality.

- Zero Gaps between rollers are adjustable.

- Easy to clean.

- Leak proof water Cooling/ Heating System to rollers.

Model Overview:

MODEL | PTRM – 80 |

Throughput- Min- Max. | 0.02 -2 Liter/Hour, Average depending on product. |

Roller Diameter | 80 mm |

Roller length | 200 mm |

Rotor Speed Ratio n1:n2;n3 | 9 : 3 : 1 |

Roller Material | Hard Chromed plated steel. |

Gap between Roller | Zero Gap Adjustable |

Universal scraper system | Standard |

Scraper knife material | Steel |

Frequency converter Speed control Motor Output | 0.75 KW |

Roller which can be cooled and heated up to 60° C | Standard |

Dimensions mm( width x depth x height with scraper system and hopper) | 750 x 600 x 600 |

Net weight – Kg | Ca. 75 |

Power supply | 3 phase & Specific Voltage. |

Additional Information:

- Item Code: PPMLTR

- Port of Dispatch: Mumbai

- Delivery Time: 4 to 6 weeks

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

Laboratory Scale Vibro Sifter

Get Latest Price

| Automation Grade | Semi-Automatic |

| Phase | 3 Phase |

| Brand | Prism |

| Type | Circular |

| Application | Food Processing |

Vibro Sifter

Compact Sieving & Grading Process Technik

Application & Process:

Vibro Sifter is used for screening, sieving, grading for solid-liquid separation, process to separate the desired elements and the undesired elements from the combination of solid to solid (where two solids are generally having different properties) and solid to liquid material.

Salient Features:

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- Powerful vibration by gyratory motion by special Vibro motor.

Additional Information:

- Item Code: pvs

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Automatic Grade | Semi-Automatic, Automatic |

| Material | Stainless Steel |

| Color | Silver |

| Power source | Electric |

Multi Mill

Lab Multi Mill

Application & Process:

Table top Laboratory Multi Mill is used for wet and dry granulation in pharmacy colleges, R&D institutions and pharmaceutical industry for research and development of pharmaceutical products.

The material is fed in the hopper, shredded and milled through beaters consisting of knife and impact edges. The rotation speed and direction of beaters could be adjusted through control panel. The material then passes through the cylindrical screen in spiral motion which helps keeping the temperature low and avoids chocking of material during the process. The material is collected in the container placed under the hopper.

Additional Information:

- Item Code: LPMTM

View Complete Details

Lab Tablet Coater

Get Latest Price

| Capacity | 1-25 KG |

| Model | PAC |

| Brand | Prism |

| Automation Grade | Automatic |

| Material | SS 316 |

| Condition | New |

| Material Grade | SS 316 |

| Size | 12",14",16",18",20",24" |

Application

The tablet to be coated make continuous complicated orbital motion the closed rotating Drum under the action of a streamline of Baffles.

Lab Auto Coater is high efficiency and intelligent automated film & sugar coating advance technology is mainly used in pharmaceutical and food industries. Featuring mechatronis and confirming to the requirement of cGMP.

Additional Information:

- Item Code: LABOcoata20

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

View Complete Details

Laboratory Scale Oscillating Granulator

Get Latest Price

PRISM® New LABOgranulator: LAB Oscillating Granulator

The Uniform Size reduction Process.

Application & Process:

The Laboratory Oscillating granulator is for wet and dry granulation widely used in research laboratories of pharmaceutical, food and chemical industries.New Design Features:

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- Uniformly granulation & fewer fines.

- Simple & compact Design.

Additional Information:

- Item Code: PPMLOG

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Usage/Application | Pharmaceutical |

| Automation Grade | Automatic |

| Material | ss304 |

PRISM® New LABOmill: Lab Cone Mill

The Wet Milling & Size reduction Process.

Application & Process:

New Design Features:

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- Uniformly granulation & fewer fines.

Additional Information:

- Item Code: PPMLC

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

Lab Fluid Bed Dryer

Get Latest Price

| Body Material | Stainless Steel |

| Batch Size (Kilogram) | 8 to 420 kg |

| Color | Silver |

| Grade | Automatic |

Lab Fluid Bed Dryer

Application & Process:

Fluid Bed Dryer model Fluid bed technology is a offer an effective and efficient method for drying and agglomerating. The Lab Fluid Bed Dryer has universal application for drying of powder and granules

The Drying process: Warm air is blown through a perforated distributor to rapidly and gently dry materials until the required residual moisture content is reached. Moisture evaporated from product is exhausted with drying air.

Additional Information:

- Item Code: PFBD5

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

Lab Coater

Get Latest Price

| Material | SS316 |

| Capacity | 1 to 27 Kg |

| Model | PAC |

| Brand | Prism |

| Automation Grade | Automatic |

| Condition | New |

| Finishing Type | Matt & Mirror |

| Material Grade | SS |

| Size | 12",14",16",18",20" |

Application

The tablet to be coated make continuous complicated orbital motion the closed rotating Drum under the action of a streamline of Baffles. During the motion coating medium automatically sprays according to the technological process and rational technological parameters, at the same time hot filtered air supplied under a negative pressure.

The hot air penetrates through the tablets core layers and is discharged from the bottom of the layers, so that the coating medium sprayed on the surface of the tablet cores will dry rapidly and evenly, thus forming a solid and smooth surface film on tablet.

Additional Information:

- Item Code: PAC12

View Complete Details

| Bowl Volume(in L) | 15 Litre |

| Body Material | Stainless Steel |

| Color | Silver |

| Brand | Prism |

| Material | Stainless Steel |

| Model | cGMP |

| Condition | New |

Designed strictly compliance with the stipulation of CGMP

Additional Information:

- Item Code: PPMPM

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by Customer

- Packaging Details: Export Worthy Packing

View Complete Details

| Body Material | Stainless Steel |

| Model | cGMP |

| Condition | New |

| Automation Grade | Automatic |

| Size | 12 Liter |

| Application | Cream Manufacturing |

| Brand | Prism |

| Material | SS |

Application

The New LABO planetary machine is used to mix Liquid to Liquid, Liquid to solid, and solid to solid are in Pharmaceutical Powder, Granules, Ointment, Cream, Galantine, Cosmetics, Food, Confectionery, Chemical and Soaps.

Schematic arrangement of mixing action of the high shear blade agitator system is contrary to conventional planetary mixer, the two blade configurations sweep the wall of the can clockwise and rotate in opposite directions at about three times the speed of travel.

Additional Information:

- Item Code: LPPM

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

| Body Material | Stainless Steel |

| Color | Silver |

| Model | cGMP |

| Condition | New |

| Capacity | 1 To 500 Kgs/batch |

| Grade | Automatic |

The New LABO planetary machine is used to mix Liquid to Liquid, Liquid to solid, and solid to solid are in Pharmaceutical Powder, Granules, Ointment, Cream, Galantine, Cosmetics, Food, Confectionery, Chemical and Soaps. It has a homogeneous mixing action and planetary motion (Single or Double Planetary) of the beater enables faster and better mixing of material. The planetary mixer is an intensive mixing, dispersing, kneading and degassing viscous, heat sensitive and above all, cohesive pastes, dough and moist, crumbly masses, such as sealing compounds, adhesives, printing inks, dental plastics, plastics, condensed soups, battery compounds, cream cracker dough, etc

Schematic arrangement of mixing action of the high shear blade agitator system is contrary to conventional planetary mixer; the two blade configurations sweep the wall of the can clockwise and rotate in opposite directions at about three times the speed of travel. The shear blades displace the material from the walls of the can and by their overlapping action the center carry the particles towards the agitator shafts, therefore producing a large field of shear forces. By this means even highly viscous and cohesive material can be efficiently mixed. . Rotation of the Planetary Blades on their own axis while they travel around the center of the mixing bowl ensures complete and effective mixing.

The Product container provided with jacketed to heat and cool with circulation of steam/ cold water. Machine can specially designed to operate under vacuum to remove air entrapment in product during mixing, open type beater to cover full cross section of product in bowl, Teflon fitted on SS scrapper provided to scrap product sticking on the bowl. Also option for customized blade design for mixing powder, Liquid, Ointment, Gel & Cream with planetary action.

Additional Information:

- Item Code: PPMLUPM

- Pay Mode Terms: L/C (Letter of Credit)

- Port of Dispatch: Mumbai

- Delivery Time: 4 Weeks

- Packaging Details: Sea Worthy or standard packing as per delivery location

View Complete Details

Laboratory Scale Pelletizer

Get Latest Price

| Machine Type | Semi-Automatic, Manual |

| Brand | Prism |

Laboratory Scale Pelletizer is implemented in the pharmaceutical, agricultural, chemical, nutraceutical industries where it is required to create pellets with uncontrolled characteristics of density, size, and surface. These technologies are implemented in multiple industries with very specific differences required for pharmaceutical batch systems and continuous systems.

The Process powder is put on the inclined cylindrical drum and they are converted into round pellets with the help of the cylindrical drums. The inclined cylindrical drum is rotate inclined and spray nozzle is fitted for fluidized / spraying of water/ binder. Due to round baffles the powder is fluidized and agglomeration and also that time fluidized the water/ binder by spray nozzle. Due to rotation of drum agglomerated granules is rotate in the drum during the pelletization process. During this movement of pellet on the rotating drum, they are get bigger size by the fluidization on the drum and converted into approximately same size of its diameter 2mm to 6 mm.

Wet Pellets are turned into spherical shape by rotating.

Salient Features:

- The powder is converted to pellet directly by fluidization of water/ binder.

- Designed as per CGMP Model – Current Good Manufacturing Practices.

- Contact parts in AISI 304 and non contact parts in AISI 304

- The machines are provided with the spraying nozzle.- 1No.

- AC frequency drive for variable speed.

- The desired RPM is achieved as the machine is fixed with A.C. controls.

Additional Information:

- Item Code: PSPD

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: Any Seaport

- Delivery Time: As Desired by customer

- Packaging Details: Export worthy wooden packing

View Complete Details

- Developed and Managed by IndiaMART InterMESH Limited